Small. Lightweight. Powerful.

For your most efficient drivetrain solution.

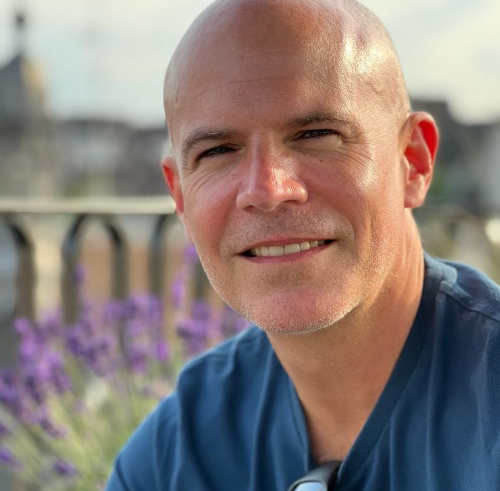

Who we are.

For over 40 years we develop and manufacture innovative electrical, electromechanical, and hydraulic solutions. This has made us a strong and internationally recognized manufacturer of high-tech medical products, cutting-edge motorsport components, and highly professional aviation applications.

Our journey began in 1975 when Bernd Sobek envisioned leveraging robust Aircraft Standards to introduce innovative solutions for diverse fluid flow needs in the realm of car racing. Since then, we have outfitted a six digit number of road vehicles with our high-quality products, established a presence in elite motorsport racing series globally, and contributed to aviation projects with our tailored solutions for several years.

Our vision, always being one step ahead in the development of innovative products, shapes our teamwork: collaborative, appreciative, providing space for personal contribution and development.

Discover what we do.

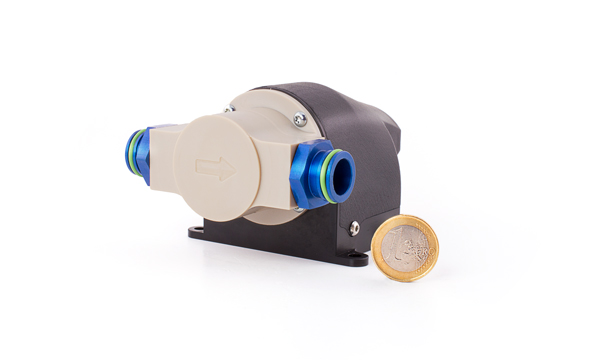

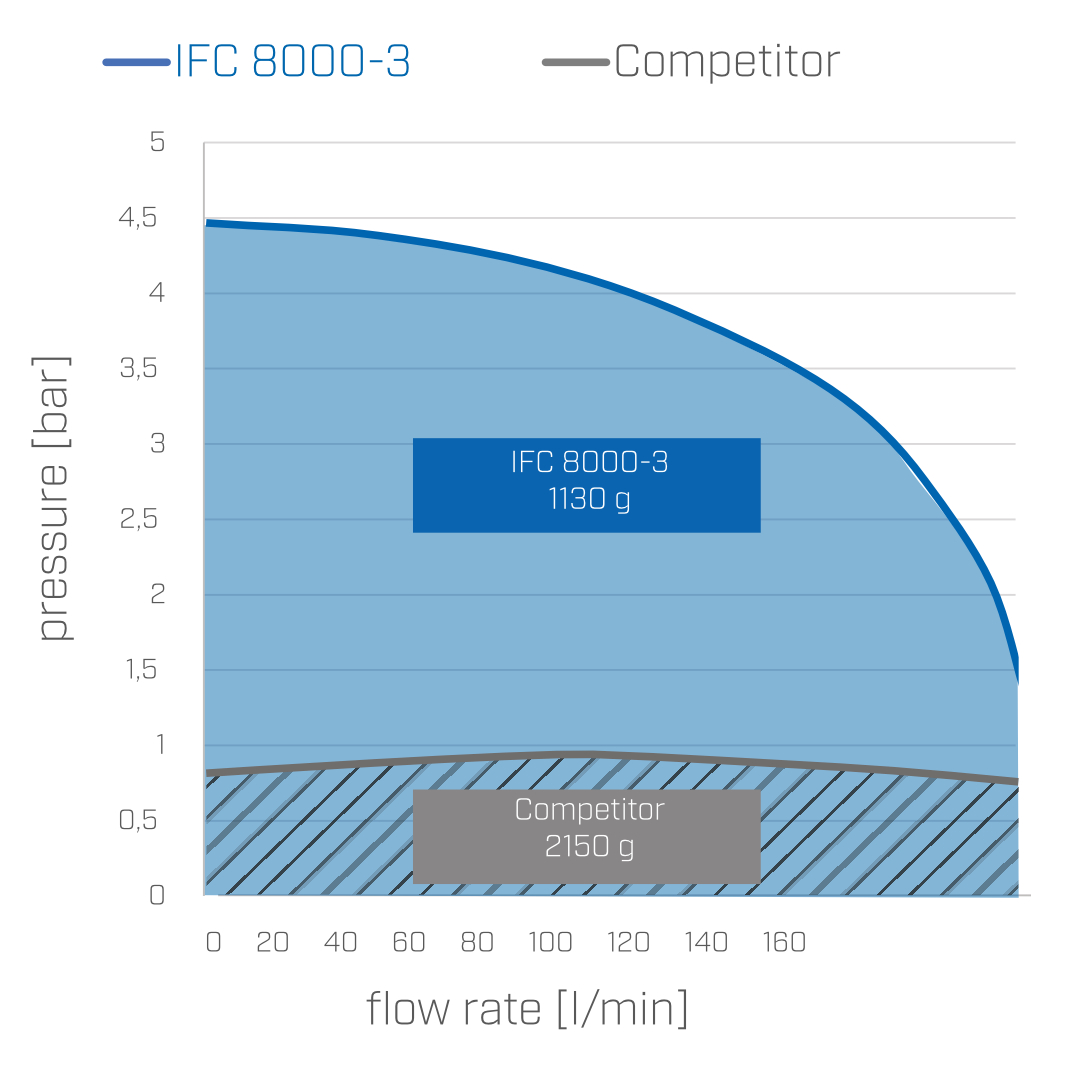

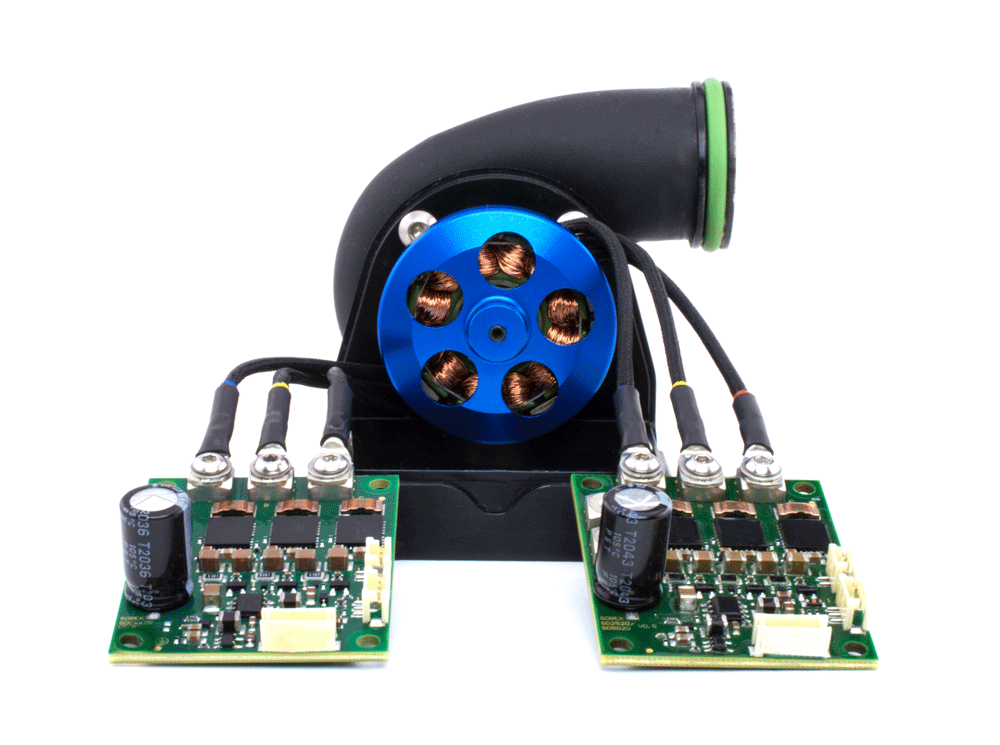

Delivering small, high-performance products with high power density is our DNA.

We start where others stop.

We come into place when applications require high-performance and modern thermal management, where redundancy systems are needed for safety-critical areas or installation space, and saving weight is an essential aspect. With our extensive expertise in hydraulic and electronic components and systems, we specialize in creating comprehensive system solutions for a wide range of applications. These include electrified transportation in the air, on water, and on land, as well as mobile applications like handheld tools. Additionally, we excel in the intelligent management of cooling systems for motors, batteries, and inverters.

The Value Of Our Products.

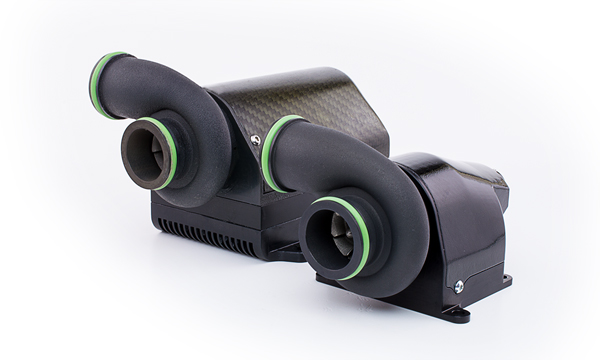

Safety – Our Redundancy System

IF ONE COMPONENT FAILS – THE SYSTEM CONTINUES

A single system failure, such as the motor, should not result in a complete system breakdown or disruption. This is precisely where SOBEK’s redundancy system plays a vital role. Its purpose is to guarantee the uninterrupted operation of a system or device, even in the event of component failures. This involves replicating essential components or functions, allowing for a smooth transition to a backup if one component fails, thus averting system downtime or failure.

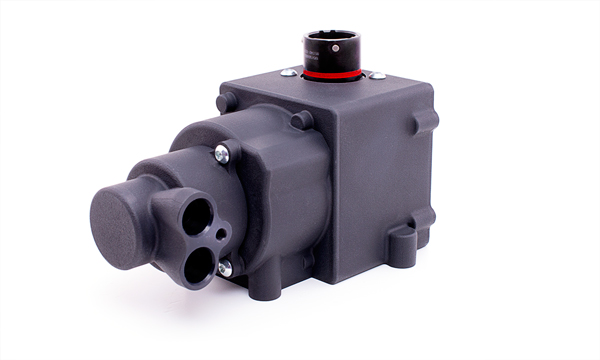

Intelligent Flow Control

Our products come with an integrated Control Electronics Unit, providing streamlined functionality and enhanced data accessibility. Embedded algorithms for temperature, torque, power, blockage control, and redundancy features ensure secure and reliable operation. These algorithms also offer real-time insights into the pump’s status, including a comprehensive fault diagnosis system (CAN, UART, LIN, PWM, etc.)

Our Industries.

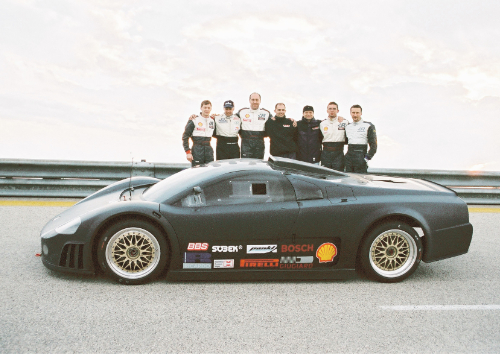

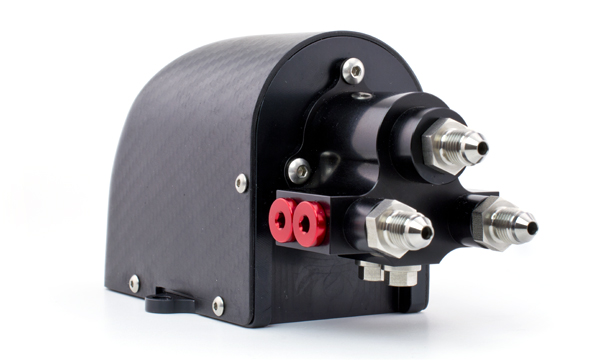

MOTORSPORTS

In a racing setting, technology pushes materials to their utmost physical thresholds. It requires a balance between technical requirements, adapting to rapidly changing scenarios, and prioritizing safety comprehension. Seen by many as the ultimate arena to test the ‘best of the best’ every motorsports company knows that winning is the only aim – second place is the first loser.

MEDTECH

The development of medical devices and equipment aims to preserve and enhance human health. Hence, the expectations placed on suppliers in this industry are exceptionally demanding.

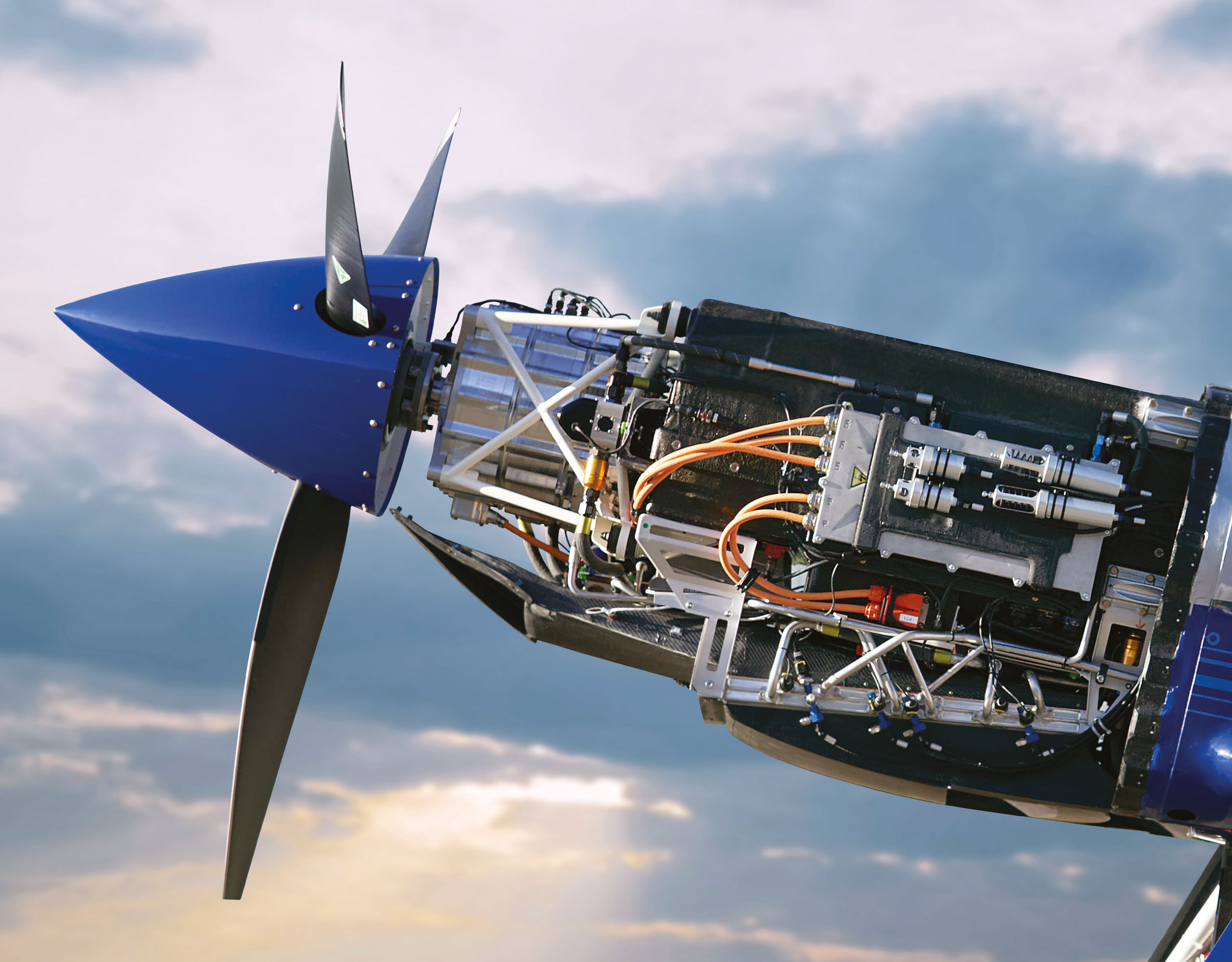

AVIATION

In the aerospace sector, the stringent demands placed on the components you acquire are unmatched. You require an unwaveringly dependable partner capable of delivering tailored solutions to every challenge. Performance standards are not just expected; they are a prerequisite. So, what provides you peace of mind when making a procurement decision?

Our EN 9100 certification serves as the ultimate assurance of the exceptional quality of our electric drive solutions, including brushless in- and outrunners, along with high-performance power controllers.

INDUSTRIAL

Our control electronics and electric motors can be found in numerous applications in industry. We can be found wherever high performance is needed. Especially in mobile applications, we can score with our small, powerful products.